Angle of inclination for vertical vs horizontal mounted solar panels

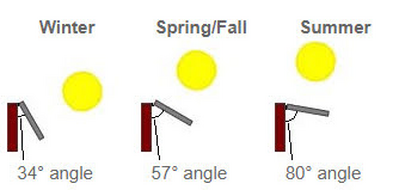

Panel inclination is measure as the incline from horizontal. So, if you are going to measure from a vertical mounting structure it would be 90 degrees - your measured angle.

My "year around" angle is approximately 34 degrees measured from horizontal, therefore if I wanted to measure from vertical it would be 56 degrees.

Best way I have found to measure is to use an inclinometer app on a phone or pick up one at Harbor freight.

Thanks,

JB

Sometimes the easiest solution is the best solution.

Sometimes not.

Tools like Footprint Hero can also be helpful, though they may be somewhat generic.

Footprint Hero Solar Panel Tilt Angle Calculator

@jared Thanks Jared. This is the one I use. https://www.inchcalculator.com/angle-of-elevation-calculator/ it was recommended by one of the installers/sales techs. I've found it useful, perhaps someone else will too.

@joel-brodeur Thanks for the info. The way you described was my original train of thought. However; self-doubt tends to creep up when you are spending this much money. 🙂

I know exactly what you mean.

I made some very $$$$ mistakes with my first system, and that was after 3 years of tutelage from someone that had made some very $$$$$$ mistakes with their first system.

I think the best thing I learned out of all of was, you can't plan for the future but if you plan for expansion you can at least mitigate the future.

🙂

JB

Sometimes the easiest solution is the best solution.

Sometimes not.

future planning and 45 years in IT have taught me to leave plenty of room for "oops that didn't pan out the way I thought it would." Situations, such as my latest upgrade from Solar gen-1.

to Solar gen-2.

Looks, fantastic.

Sounds like cooling is a challenge in your area. For me it is heating. I just haven't found great solution. Yet...

Sometimes the easiest solution is the best solution.

Sometimes not.

The current challenge staring me in the face is our first freeze. Whenever that happens. We only get about two weeks of real winter; but it is scattered across 3 months, so I have to figure out how to continue to water AND not have my pumps freeze on the nights (and some days) it drops below freezing. Lines are mostly underground but pumps are exposed until i can build a full pumphouse. All of the connections are USA Brass so not worried about them cracking/breaking (overseas made union split at 30F) on my 2500 gal tank.

Had a similar issue when we first got our water system up and running.

Wasn't able to get installed until late October and wasn't going to be able to finish up for a couple of weeks.

I used two solutions:

1 - Wrapped everything in thermostatically controlled heat tape (talk about a power drain but needed in our circumstances).

2 - Build a box out of 4" foam board and duct tape, then stuffed the whole thing with some bat insulation (thhis helped keep the tape from coming on too often).

With all of that I was able to survive a couple of weeks until I got everything situated as needed.

It was probably a little overkill, but we can go from 20F above to 40F below overnight.

JB

Sometimes the easiest solution is the best solution.

Sometimes not.

I tried "industrial" heat trace on my small off grid system 1st. Then found it it's "self regulating" feature isn't used to determine when to come on but instead not to get too hot. 16amps on a 50' run made me pull it all out (without following up with another pull string for my partially underground setup) quick and go with the big box on at 32 degree heat trace on each end instead. 1.6amps at 25' is working well.

- 37 Forums

- 1,021 Topics

- 5,519 Posts

- 0 Online

- 1,588 Members