North Central Texas Setup Just about to turn a year old!

Four years ago we purchased 4 acres of land in Parker County TX.

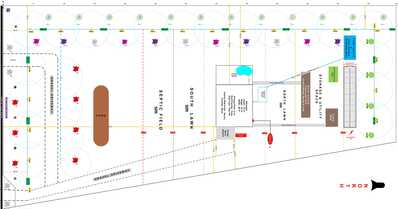

My thought was that I would get the infrastructure in place while we worked on getting the house built. So I made a detailed plan down to the foot of what I wanted to do and made sure I got it all approved by the POA.

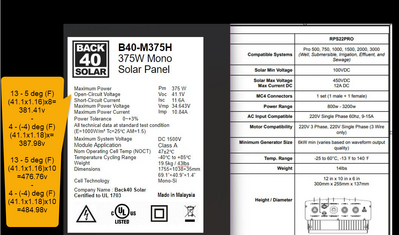

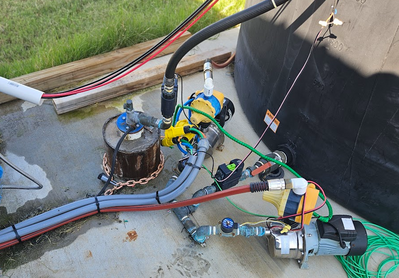

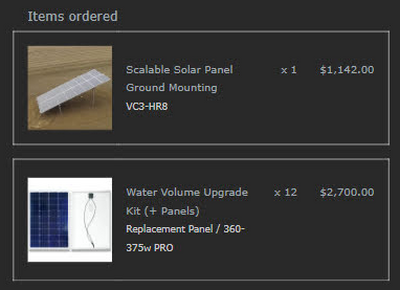

I quickly realized that with a well that only produced 5 gal a minute, I had a few problems to work out. The first of which was how I was going to get water to the surface and stored. That is where I was introduced to the RPS folks and their Solar Pumps and their line of pumps & panels. I settled for the RPS 800 Kit because I already had the well head in place. https://shop.rpssolarpumps.com/products/rps-800-solar-well-pump-kit-formally-rps-2-1-100?variant=5770768384038

along with the ground mount package.

I also decided that I wanted to be able to run the westinghouse 9500w generator if required. I split the build site into a water side and an Inverter side. Right now I have two solar strings to the 6000XP (only one is active right now)

I am planning on adding 12 more solar panels this winter and another battery next spring.

How is the system performing? Does it carry as expected? What would you change if anything?

The pics are great. This is a retirement goal of mine. So I am only about 45 years away from this.

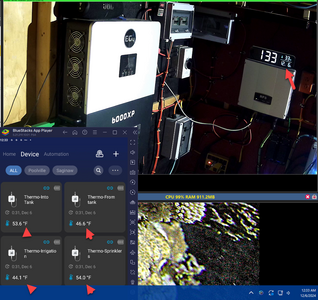

@herque I have had ZERO problems with the 6000xp (other than the wi-fi dongle, I finally just went wired). It has handled everything I have thrown at it. The heat did not seem to affect it too much. I LOVE the auto recovery features. I am about 40 miles from my property so those are a big help. When I drain my battery down too low, the output shuts off (cable modem is on a ups so reporting does not stop) until it has recharged above the cutoff threshold. A model I "tried" did not do that, so if I lost connection for any reason, it was a 2 hour drive...

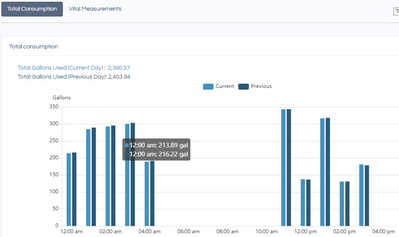

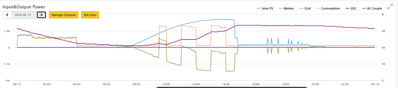

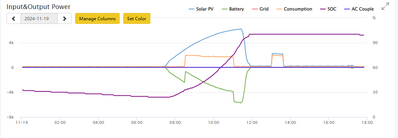

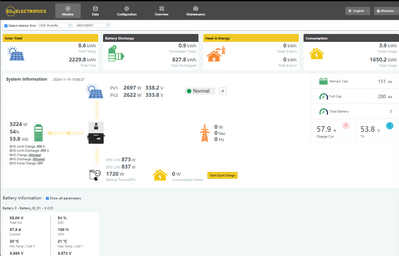

My PV curves over the summer were excellent. They looked like the one below just longer due to the length of the days.

The consumption during the day are the refill cycles. The pump and well refresh rate are almost exactly the same, so I take a 15-30 minute breaks to allow for any makeup. The irrigation begins at midnight and runs until 0440 pushing out just over 1300 gallons.

for next summer I plan to add the EG4 mini-split (after adding panels over the winter).

That is great data. I will say this. The mini split is awesome!!!! Totally worth it and the install was simple. I have one on my little shed. It needs 90 volts to start up but runs around 400 watts. I absolutely love it. You will too.

I look at the app only 3 or 4 hundred times a day.

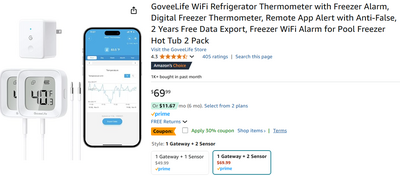

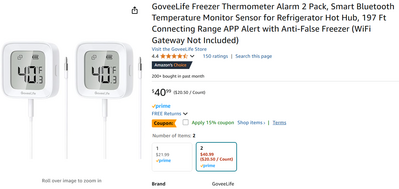

Because I live so far away from my property I have found it quite handy to have all of my irrigation, sprinkler and well pumps on wi-fi timers so that I can shut things off if i need to (last week my tank float got stuck and would not stop filling; When i noticed on that the Inverter was still putting out 220v instead of charging). When i checked the camera i could see the water overflow and remotely shut off the well pump.

Amazon URL ==> www.amazon.com/dp/B0C1R5255D?ref=ppx_yo2ov_dt_b_fed_asin_title

The problem I foresee with the EG4 mini split is that it runs 24x7. I am not sure how big of an impact that will have on my daily routine.

By spring i should be running a total of 7700w x .75 = (5775w avg output) and I should have another 14.4 battery by late spring. I'm doing my calculations based on 6 hours of recharge time. My biggest concern is the summer overnight draw-down when our overnight temp does not drop below 80 and i am putting down 1500 -2000 gal a night at peak summer watering.

Here is the building. 10x16x14h I am looking at using the largest i can find. The building is not insulated and the middle is open to the roof; so there is going to be a LOT of wasted air. I am trying to figure out a way to install a "ceiling" so i can reduce the cooled sq.ft.

How NOT to burn-up all of my gear during our annual Two weeks of winter. However it is usually not all at one time.

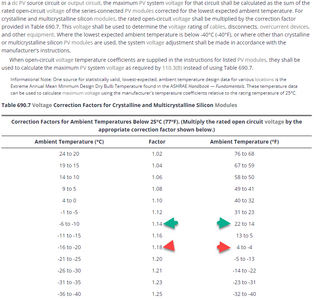

if I did the math correctly i can run 10 panels on each string but would have to turn off the 1st string (375w) if the forecast calls for zero degrees (F) or lower.

Can I get a sanity check on aisle 3 please? anybody!

Now that I have a well pump running on solar (w/generator backup) and the 6000XP PV string one with 8 375w panels attached I am able to keep the tank filled on a daily basis.

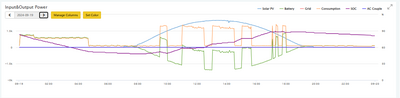

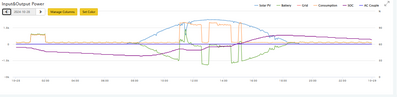

However as fall progresses to winter I notice that I do not have enough solar power to run the Irrigation, sprinklers and refill the tank within my "sun-hours" window, especially with the reduction in sun-hours. Here you see the charts from summer, mid-summer & early fall, The refill cycles happen during daylight hours for obvious reasons (2000w per hour). I leave 15 minutes between 90 minute fill cycles to allow the well to catch-up on the off chance my pump out produces the well-flow. Although they are closely matched, in the middle of the summer it can/does happen.

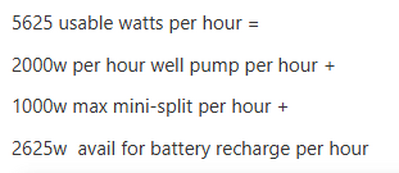

That being the case, today I ordered 12 more 375w panels and the ground mount rails to hold them. I have hired a contractor to install the additional 4 poles that need to be added to existing structure. (10*375)*.75=2812w per PV string or approx. 5625 avg usable watts per hour. This should allow me to water for 4.5 hours during the overnight, then begin recharging at first light and by about 9am I should have enough power on most clear days to refill the tank, recharge the battery and still have enough left to run the mini-split i plan to install before Summer arrives.

5625 usable watts per hour =

2000w per hour well pump per hour +

1000w max mini-split per hour +

2625w avail for battery recharge per hour

The equipment will be here on the 7th. This will fully populate my current 6000xp and leave me enough headroom so that during MOST winters I won't have to shut the system down. This will leave only the mini-split to be purchased and install in the spring.

They have arrived! ![]() A bit delayed by NM Snowstorm. . .

A bit delayed by NM Snowstorm. . .

Thank You. RPS & FedEx!

The new posts have been set but not yet cut to height (hardware is on the pallet)

and the shelf has been painted and installed with room for air circulation and to ensure to possible way to contact. Brackets are installed to support 1100lbs each (probably advertising, I'm good with 1100lbs for the three of them!).

The two power-strips that were at the ceiling level in earlier photos are now both behind the green vertical of the shelf. All of the cabling runs through holes drilled through the joist so they could route to the 6000xp.

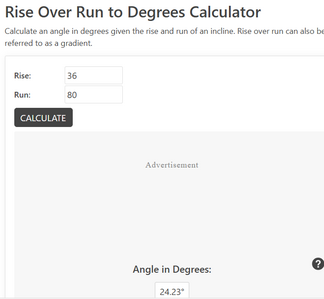

Installation Day! 🍷 7 hours to deconstruct existing ground-mount system, including removal of panels. Afterwards we proceeded to extend the ground mount by 10 feet and increase my inclination angle to a year-round 24 deg; up from the 8 degrees used for max summer power. I will run the new angle for a year and compare to this year.

We just managed to get the panels remounted before the afternoon thunderstorms forced us to call it quits for the day. It will be raining for the next two days so i will go our as soon as I can to connect int to two strings of ten panels and hook them the the 6000xp.

Oh Boy! I love it when things go right (at least for now).

Here is the math i produced in an earlier of what my Planned power would be during Summer Peak.

Here is the daily chart from the last clear day before the upgrade.

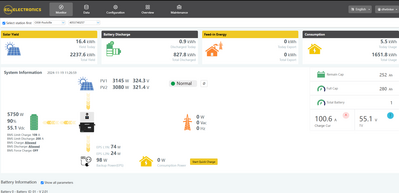

Today was the first full day of production and the sky was crustal clear and 76 degrees.

as it approached 0800 cst SOC was down around 24% but quickly rose from there.

I started running the well pump (1700-2000w) to begin the normal refill and of course there was more than enough for the charging.

Just before noon, the refill was complete and SOC was 90%

based on these number a month before winter solstice I should be more than prepared for the mini-split addition in February.

Total peak production at noon. 6225W

well pump 1700 - 2000W

max heat pump 1000W

remaining for charging 3525 -3225W

This is all roses and sunshine right now, but now how do i calculate the power loss due to the heat increase in summer when temp hits 115 degrees. That is the next issue.... after I figure out how to keep my pumps from freezing.

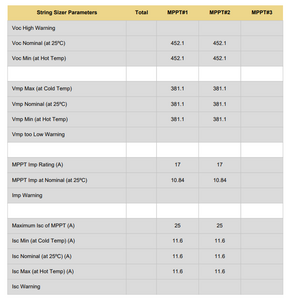

Someone (@jared) posted that we should check out the EG4 tools site, specifically the "sizer" tool.

I put in the specifics of my panels to see how close my build actually comes to the "recommended" build for a 6000XP.

Pretty close. I have two strings of 10 panels. I didn't want the extra expense and PIA for two extra panels.

Pretty cool stuff. Thanks EG4

Well that was an unexpected break! Cable at the property went down around 1105 DST on Wednesday. Turns out the cable had been broken 40 foot from the building, but there were no signs of digging. Anyway while waiting for my 0800-1200 appointment with the cable tech (and waiting for him to run 400 ft of new cable) I decided to "field day" the shed "sort-of" ![]() It was suggested by someone who shall remain anonymous; that I should memorialize the event. So I did!

It was suggested by someone who shall remain anonymous; that I should memorialize the event. So I did! ![]() Now it is obvious where the other two batteries and the mini-split are going. I just need time and $$$$ Nothing much....

Now it is obvious where the other two batteries and the mini-split are going. I just need time and $$$$ Nothing much....

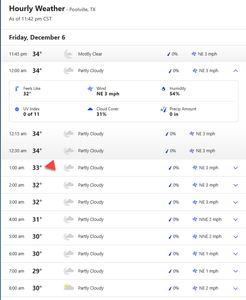

So overnight we had our first freeze. Here in North Central Texas that does not usually last long, but long enough to crack pump casings and such.

I really had no idea what to use so i picked up some heat tape from Amazon (more than i needed really 80ft) that supplied 5 watts per foot.

I created a couple of loops for each pump (tank AND motor ends) and secured with duct tape (classy right!... not). I did the same with the two flow meters and along the feeder pipes. I also attached a temp probe to each pump and to each flow controller (another pair was ordered for the main 2in outlet, and and extra just to tape to the tank wall around the tank outlet to make sure that does not freeze.

The temps hit the trigger point just after 1230 (< 35 degrees for 10 min) as advertised

and quickly raised the temps by 10 degrees. By the time it was actually freezing, all tanks and pipes were 10-15 (or more) degrees above the freeze point.

This gap was maintained over the next 8 hours without a problem.

It will be interesting to see how it all behaves with colder temps for longer periods but for not this is a keeper. I am trying to figure out how to surround the major pieces with expandable foam covers. I have ordered some large bags like these, but I have to figure out how to control the expansion of the foam until it hardens. I plan on putting this over the coils. huuuuummmmmmm I wonder.... more thought and planning

no photos of the tape job (take my word, it was horrid!). Going to chart the next week and see how it goes.

@dfwtinker Yay! You made through the first one. My place is in the mountains of Montana, I wonder if I wrap that tape and spay foam a box around the whole house. 🙂

Glad you made it through it and can't wait to see how you dress it up.

JB

Sometimes the easiest solution is the best solution.

Sometimes not.

- 37 Forums

- 1,034 Topics

- 5,610 Posts

- 10 Online

- 1,601 Members